The raw material for these cylindrical drums is High-Density Poly Ethylene (HDPE). These drums have high durability and strength, with light weight. This makes them cost-effective and superior to other types of drums manufactured from different raw materials.

We can manufacture these drums in thicknesses varying from 1.5 mm to 2.2 mm, which usually depends on our customer industry segments.

We can adjust the drum weight by changing the wall thickness of the drums. We can also adjust the height of the drum’s main body or wall. Hence, drums with varying

capacities from 10 to 27 liters can be manufactured easily.

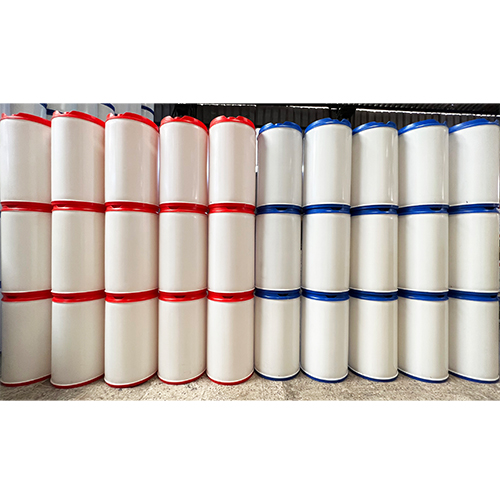

We can customize the top and bottom colours to suit client requirements. We can

customize the drum surface or wall (pipe) with the same colour matching the top and bottom colours. However, this requires a minimum quantity order. This feature makes the drum attractive due to its different top / bottom colours.

We can also customize the drums by screen printing up to 4 colours on the main body or the wall of the drum. The screen printing on the drums gives an extra appealing look to the drums where customer's branding is represented through this screen printing.

YUNIVSHA drums exhibit high reliability and security due to their ease of handling,

storage, and distribution. Due to the flat bottom, it is easy and secure to stack these drums in a 1 + 2 stacked height form without an unbalance. Hence they are called

HDPE Stackable Drums as well.

The stacking feature saves storage space and facilitates convenient transit of the drums or the transit of finished products in these drums. A large, easy-grip handle enables easy handling as well.

The smooth drum wall or the surface is an advantage for 4-colour screen printing. This helps in customer branding. The drums look more attractive and gives a better appeal to the end user. Apart from the aesthetics, the clarity of the fine print gives a visually attractive look to the drum post printing. We can supply drums with various body colour options and matching or contrasting ends. These are particularly valuable for companies wishing to code different products or to reflect their Corporate image.

The threaded cap facilitates the tight closing of the drum opening. The tamper-proof ring on the lid ensures that it won’t open until the ring around it breaks once the lid is closed tightly. This confirms that the cap is tamper-proof. This gives added security to the cap and customers can ship their products to their end destinations without the drums being tampered.

Tamper-proof vent caps work with the same principle as tamper-proof drum caps, with an additional feature of a vent hole. This allows venting the gas or degassing of certain chemicals that release gases.